Share this post

Bulk wine shipping: Getting your wine from storage to market

Table of contents

- What is bulk wine shipping, and what does it involve?

- Lanchester Wines and Hillebrand Gori talk bulk wine shipping logistics

- What should the world know about Lanchester Wines?

- Why have you worked with Hillebrand Gori since 2005?

- How do you manage bulk wine containers once they arrive in the UK?

- What happens to the flexitanks once you’ve discharged the wine?

- What other savings and benefits can be made by bottling in the UK?

If you are in the business of shipping wine, then you know that it is a delicate process.

Wine needs to be shipped at the right temperature and must comply with certain laws and regulations. That’s why it’s important to be familiar with the ins and outs of bulk wine shipping.

Here are a few things you should know.

What is bulk wine shipping, and what does it involve?

Bulk wine shipping is the process of transporting wine in large quantities, and when it comes to logistics, there are a few things you need to consider.

Bulk wine shipping laws: There are many laws and regulations surrounding the shipping of alcohol, so it’s essential to stay up to date on the latest rules. If regulations aren’t followed, it could result in hefty fines and penalties. It can also delay shipments.

Quantity and quality: When done correctly, bulk wine shipping can help you save money and maintain a consistent supply. Because the deterioration process begins the minute wine is bottled, selecting a bulk wine shipping partner that can guarantee quality and quantity is crucial.

Lanchester Wines and Hillebrand Gori talk bulk wine shipping logistics

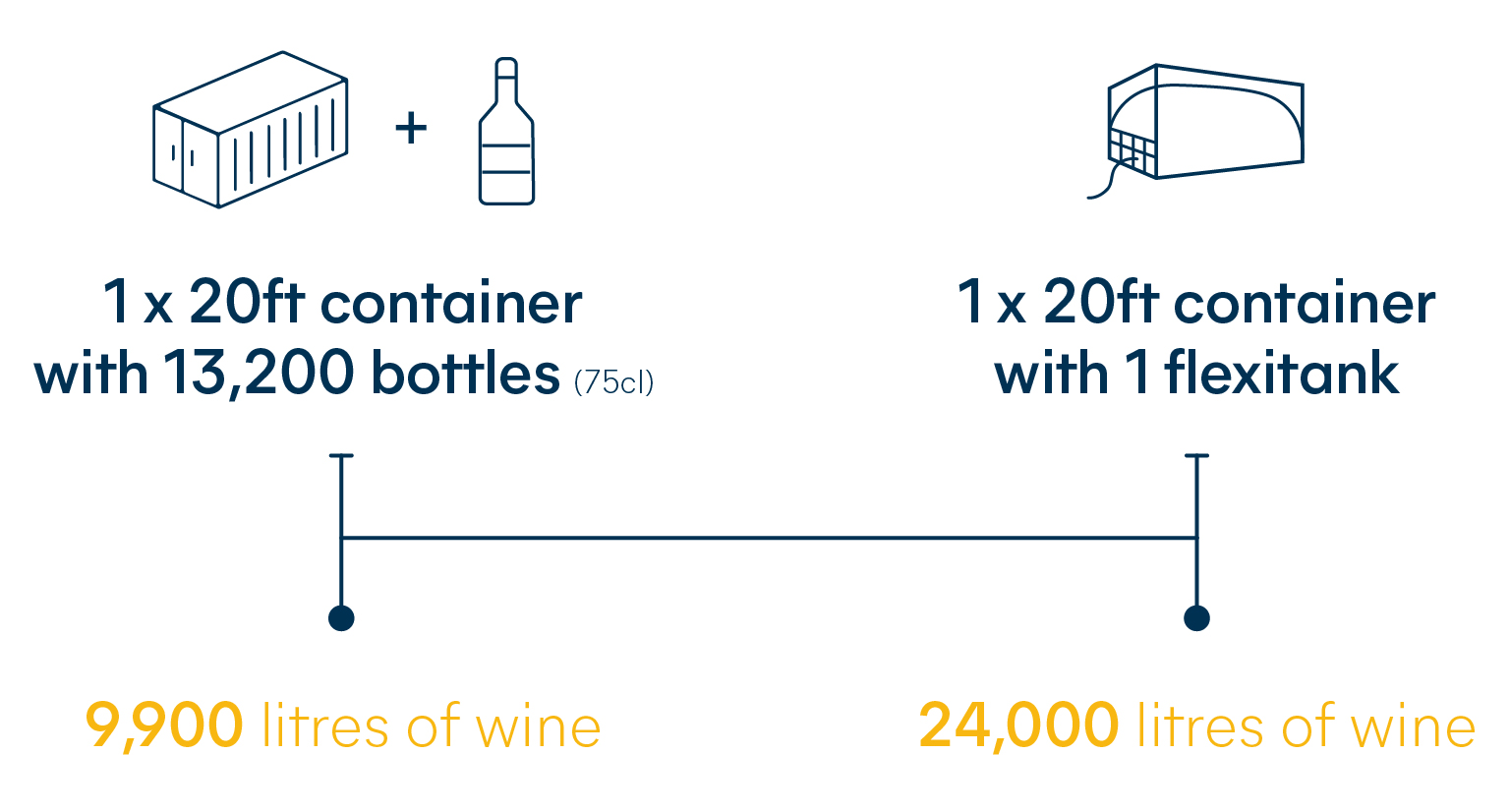

We often speak about how shipping in a flexitank can prove advantageous compared to shipping in bottles; the most obvious benefit is you can double the amount of volume shipped.

With that comes a significant win on the environmental front, with CO2 savings of up to 40%. We’ve worked it out as around 2kg of CO2 per km travelled. But here’s what else you need to know!

We spoke to Lesley Cook, Director of Purchasing at Lanchester Wines, about how bulk wine shipping with Hillebrand Gori and bottling it in the UK with its sister company Greencroft Bottling has elevated their business in the drinks industry.

What should the world know about Lanchester Wines?

We’re an independent, family-owned supplier of quality wines and spirits to the trade.

Established in 1980, we’re headquartered in County Durham but operate nationally across every element of UK wine import and export. We have over 3,000 product lines comprising bulk, boutique bulk and bottled wines, which provide our customers with wines to meet every requirement, from premium ranges to award-winning house wines and everything in between.

We are a sustainable wine company and strongly believe it’s the duty of every business to preserve our planet, which is why we’ve invested over £8.5million in developing clean, renewable energy and heat generation for our offices and warehouses to greatly reduce our business’s carbon footprint. Today our business is powered almost completely by renewable wind and solar energy because we believe being carbon neutral is just the beginning.

Why have you worked with Hillebrand Gori since 2005?

Originally, our relationship with Hillebrand was for shipping bottled goods out of Chile (around 2005), which we still do.

And in 2012, we expanded our working relationship with Hillebrand Gori into also importing bulk wine, specifically deep sea (new world wines). Bulk allows us to develop a more personal service for our customers – flexibility of wine, packaging and flexibility of format, which in turn creates a more tailored product.

Bulk provides us with the freedom to explore options such as personalisation, own label and range development. Because the transportation of bulk wine is so important to our business, we need a partner business who is proactive, dependable and provides a quality service, all of which we find with Hillebrand.

The Hillebrand Gori team has strong relationships with shipping lines and is proactive to customer needs, which, in our view, makes them a dependable logistics partner. They’ve an unrivalled knowledge of the way in which beverages need to be transported too.

The research they do on how to preserve the quality of products whilst in storage and in transit informs the development of their flexitanks, which is why we trust them with our wines.

How do you manage bulk wine containers once they arrive in the UK?

Where possible, Hillebrand Gori moves our containers to our Greencroft bottling facility using feeder services.

They take our wines to the Port of Tyne in Newcastle or Teesport near Middlesbrough, rather than bringing them through Felixstowe and Tilbury to minimise road travel time, and therefore reduce CO2 per journey, which saves:

45% in carbon emissions using northeastern ports compared to bringing products by rail from the south

68% in carbon emissions compared to bringing products by road from Felixstowe

Currently, around three-quarters of all the wine bottled at our Greencroft facility comes through northeastern ports in this way.

What happens to the flexitanks once you’ve discharged the wine?

In short, we recycle them.

We are proud to say that by working with Hillebrand Gori, 100% of the flexitanks we use are mechanically recycled. Hillebrand Gori also collects the bulkheads that hold the flexitank in place in the container and away from the door.

They repair and refurbish them, so they can be reused in future bulk shipments. Both companies are committed towards sustainable operations and actively pursuing a circular economy for equipment used.

What other savings and benefits can be made by bottling in the UK?

Firstly, have you compared the cost of a glass bottle to that of a lightweight glass bottle?

Same durability but not as expensive. Also, and arguably, more importantly, lightweight glass uses less raw material in its manufacture, and so it ticks the environmental benefits box too.

For example. We switched 98% of one of our customer’s wine portfolios to lightweight bottles, and we found a reduction of 13,577 tons of glass, which meant a reduction of 14,127 tons of CO2 emission.

For more information on the sustainability of our flexitanks, look at this study by Carbon Footprint.

Published 14th October 2021, updated 19th January 2024

Bulk wine refers to large quantities of wine being transported in flexitanks or ISO tank container. This method of transportation allows for more efficient and cost-effective shipping.

An efficient way to ship wine in bulk is through Flexitanks. These large, single-use tanks can hold up to 24,000 liters of wine. Work with a freight forwarder specialising in wine logistics, like Hillebrand Gori, to ensure the safe and efficient transportation of your wine.

The International Maritime Organization has specific regulations and standards for transporting bulk liquids. These standards cover quality control, safety, and environmental considerations. Each country may also have regulatory bodies overseeing the import and export of bulk wine.

By eliminating the need for individual bottles and packaging, bulk shipping significantly reduces transportation costs. It also allows for more efficient use of space, as a single flexitank can hold almost double the amount of wine compared to bottles in a container. This reduces the number of shipments needed, reducing costs and carbon emissions. Additionally, it helps eliminate waste from packaging materials, making it a more environmentally friendly option.

How can we help your business grow?