Flexitank recovery and recycling contributes to a sustainable world

Carbon Footprint Standards™ say were a green solution

Shipping in bulk is often more sustainable than shipping packaged goods, as more liquid can be carried in a single container. But how green our flexitank and bulk liquid shipping really is needed independent review.

Full traceability and visibility

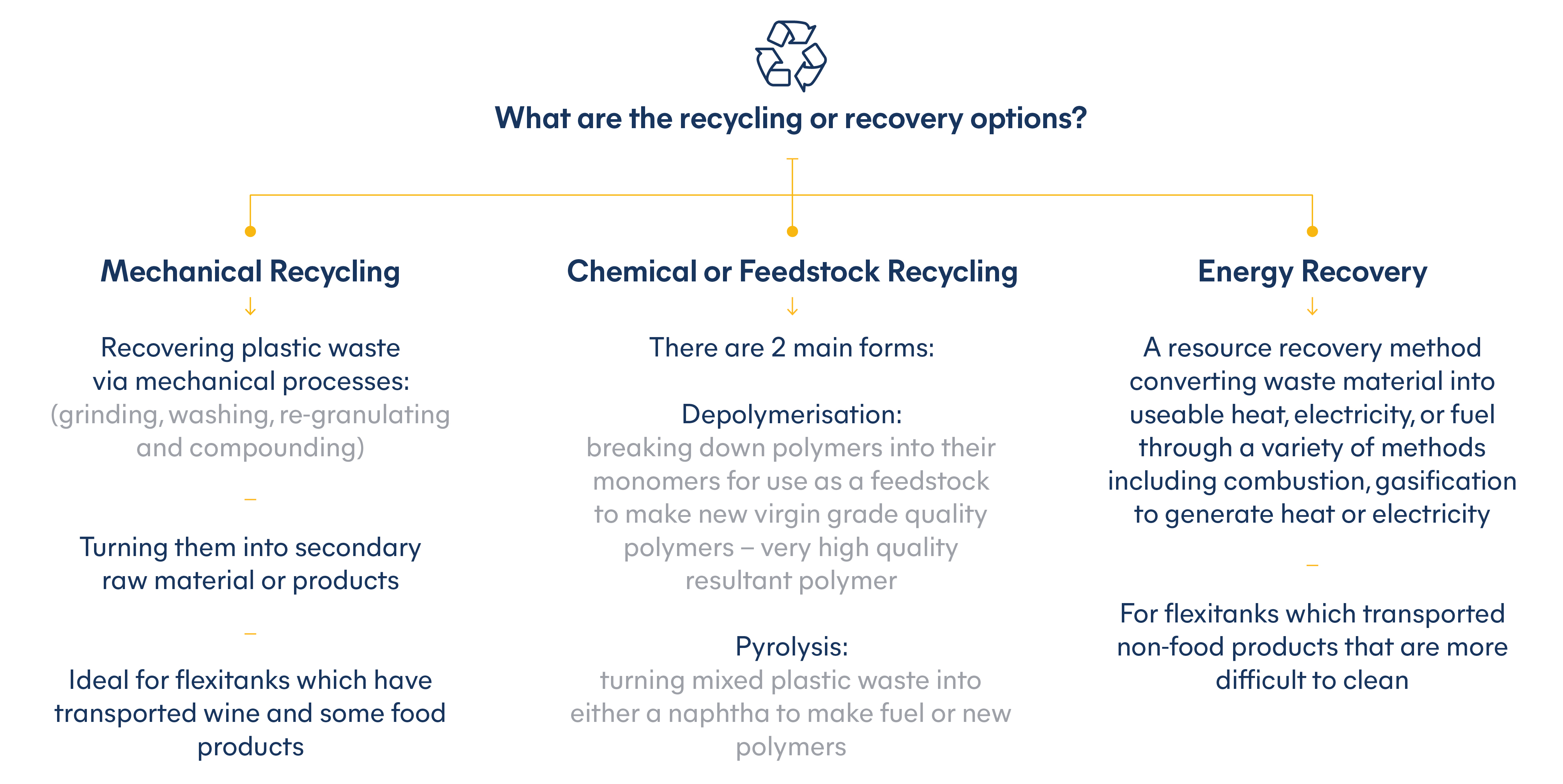

We guarantee the recyclability of our equipment. We source the polyethylene film, we design the flexitanks, we manufacture all our equipment in our own facilities and aide customers with the recovery and recycling of them.

Say no to landfill. There is a better way.

We reuse our bulkheads

Promoting a circular economy means taking steps to recover and reuse the equipment we produce. We collect, repair and refurbish our bulkheads from every flexitank shipment so we can reuse them. Just let us know when to collect them.

How can we help your business grow?